COMPLETED WORKS

|

|

|

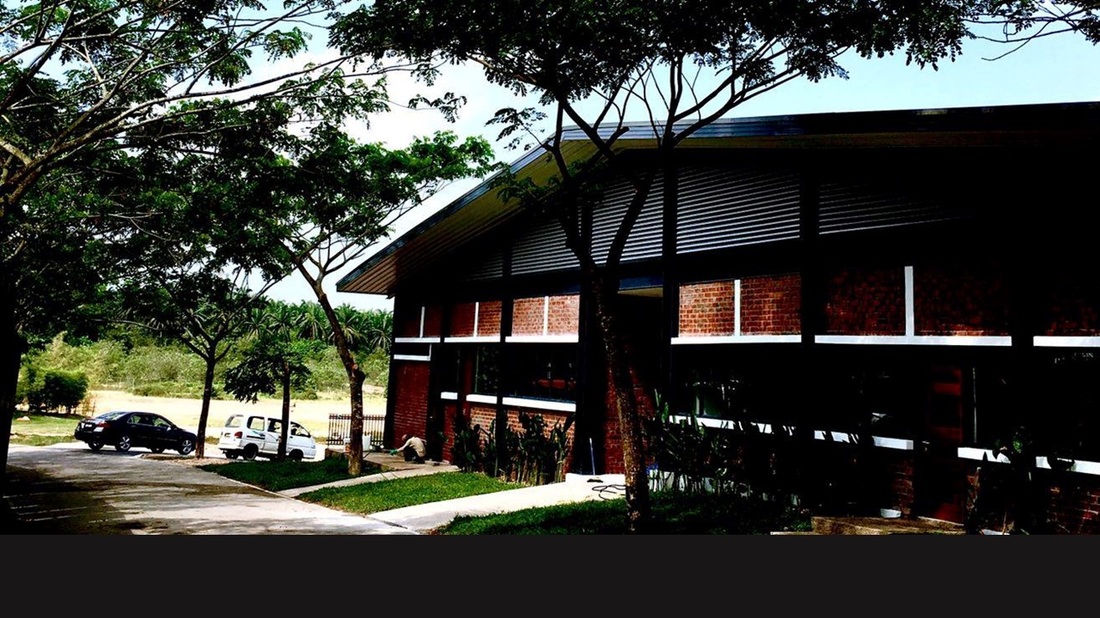

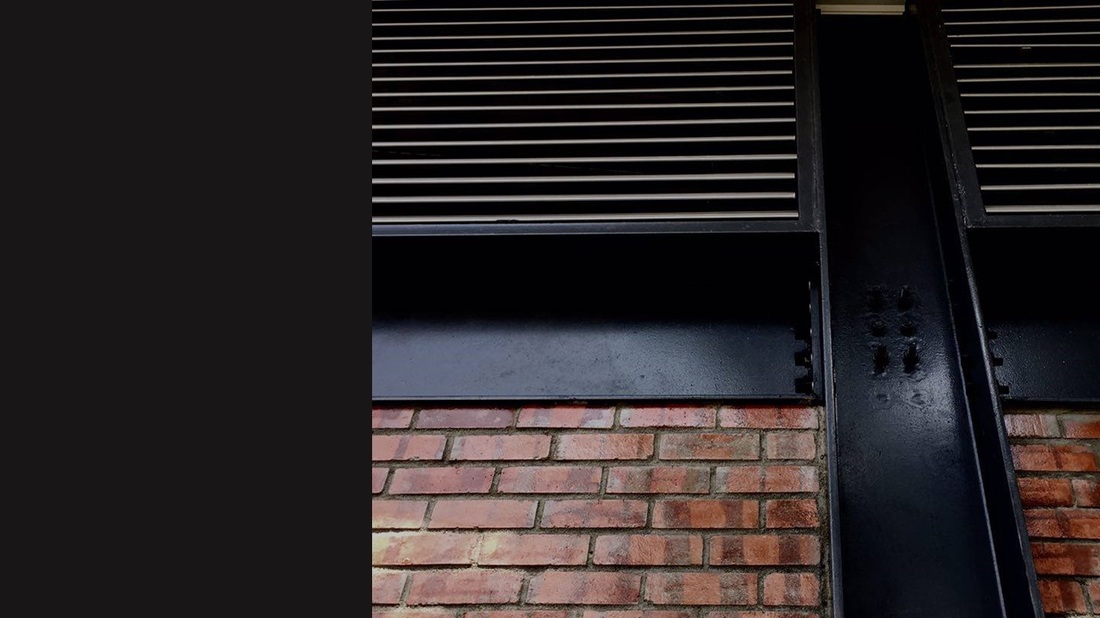

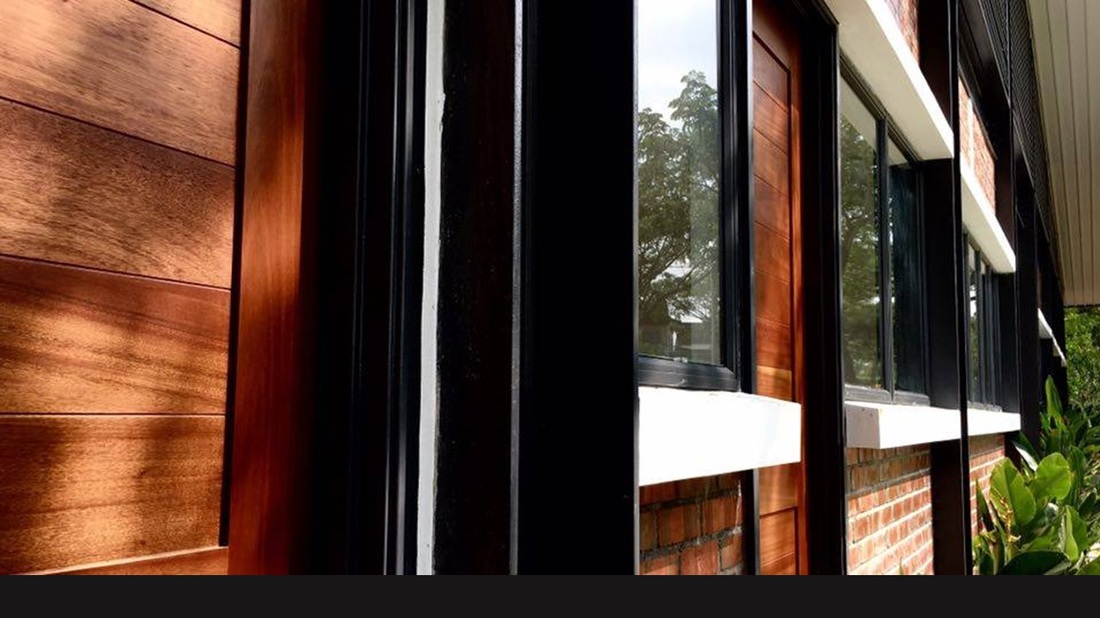

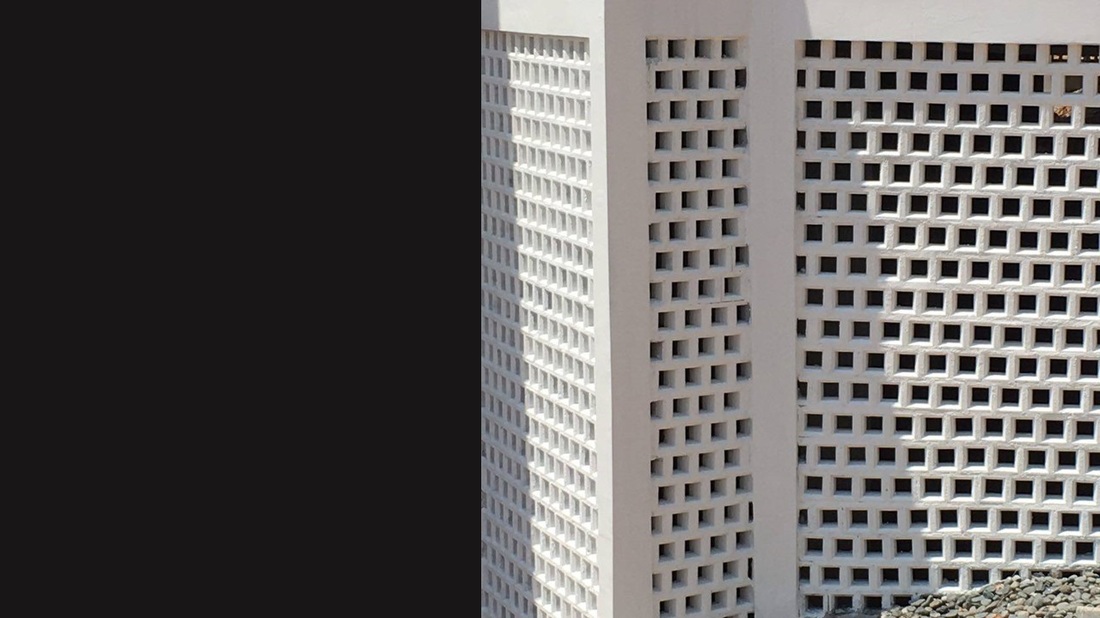

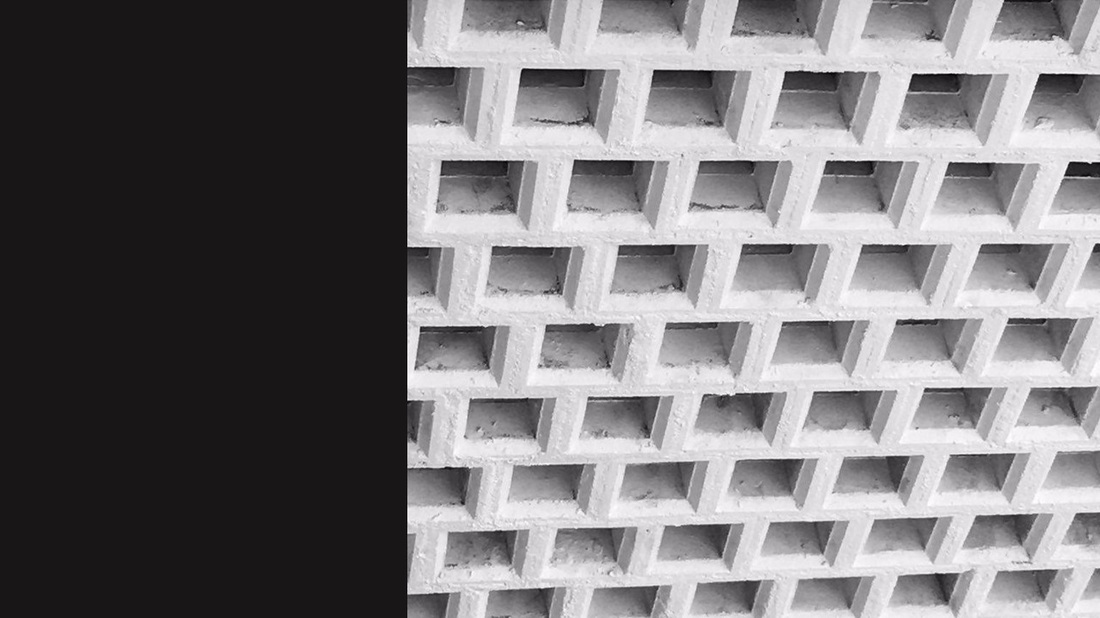

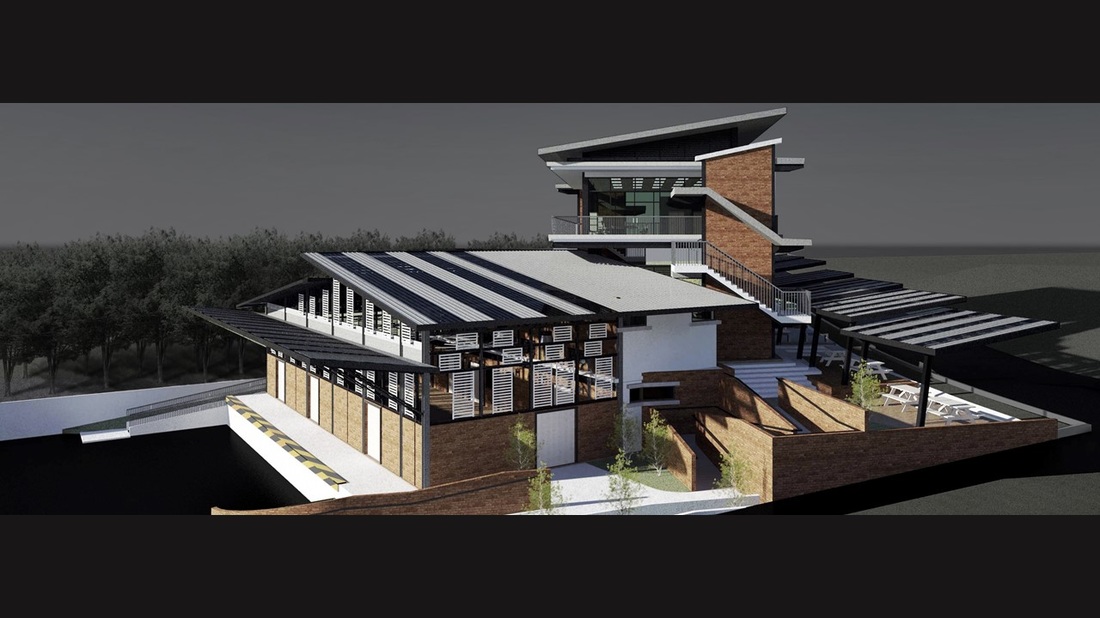

This is the first attempt for us to create a building in a form that is RAW, celebrating the truth to materials without the need to conceal the natural building materials. The primary materials usage shall be Steel, Bond Deck, Concrete Slab, Common Brick, Aluminum Louvre and Vent Blocks. The main structure was built upon Steel Frames with Bond Deck RC flooring. The Walls are primary Common Brick unplaster, insert with occasional lintel beams and stiffeners. Roofing shall be Metal Deck standing seam.

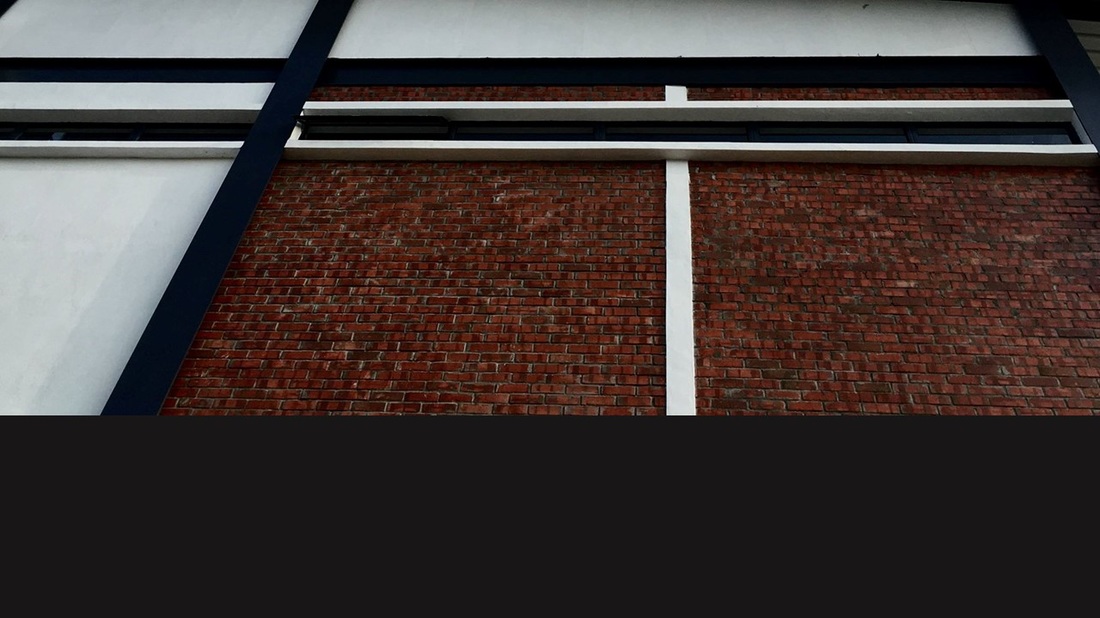

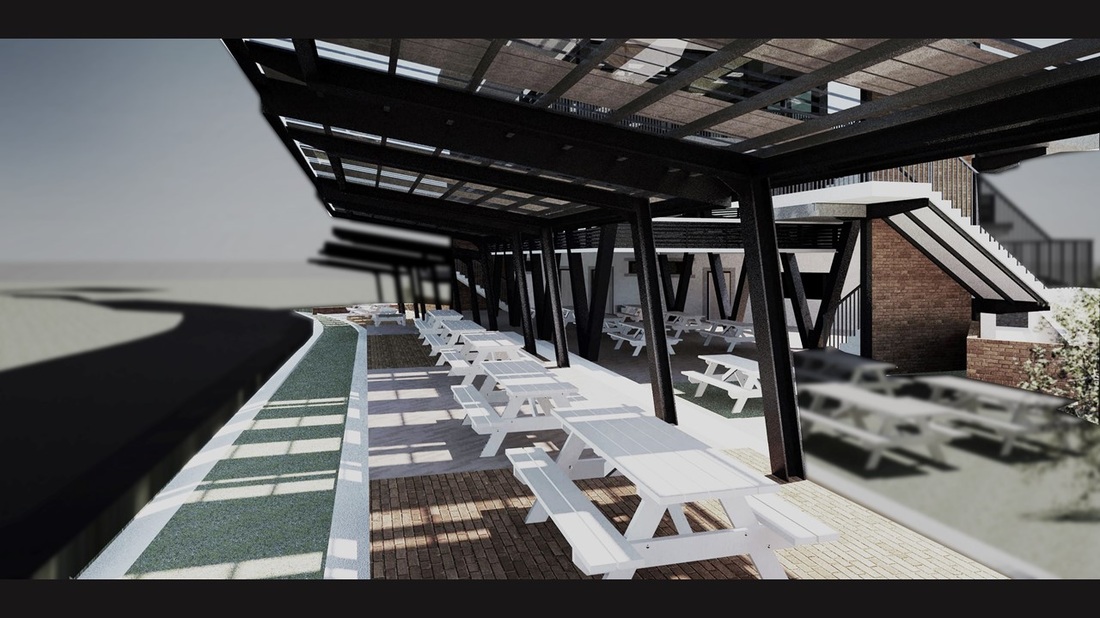

SUN SHADES AND COMMON BRICK WALLS

Celebrating the phenomenology of natural materials scented by the breeze and shade of natures. Trees are very much preserved and with the early beam of the morning sunlight, patterns are formed within the rough surface of the warm common brick wall laced with the cold darken steel structure and complimented by the white washed coping and lintel beams. Every blend of shades from the extreme Dark Grey to the bright Common Brick are truly manifested beyond any superfluous need to describe. A truly work of God against the backdrop canvas so provided by the Architect.

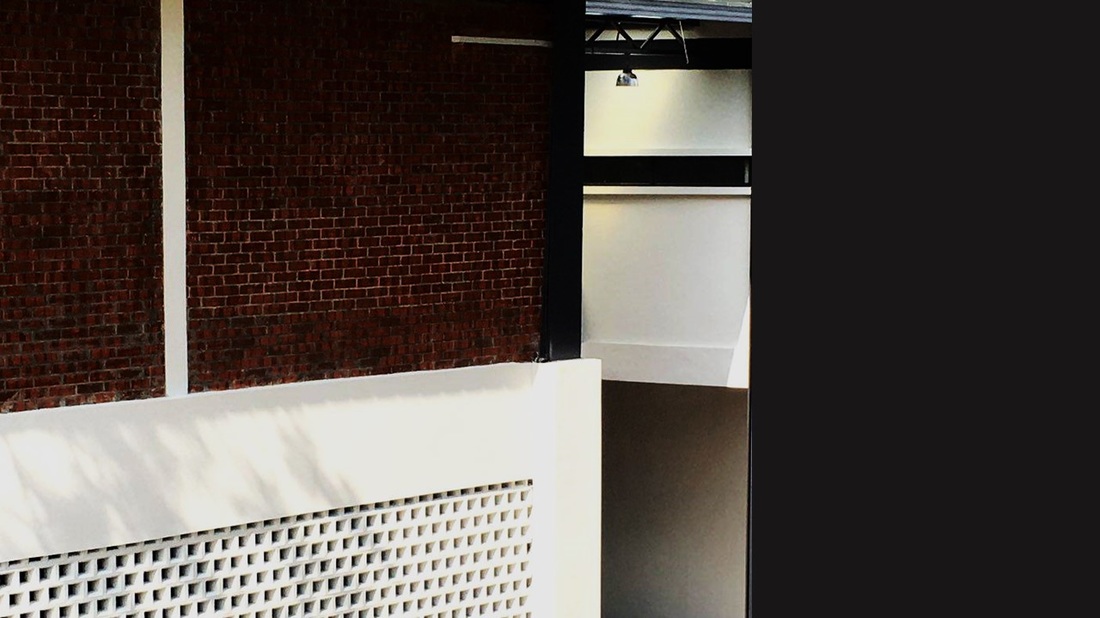

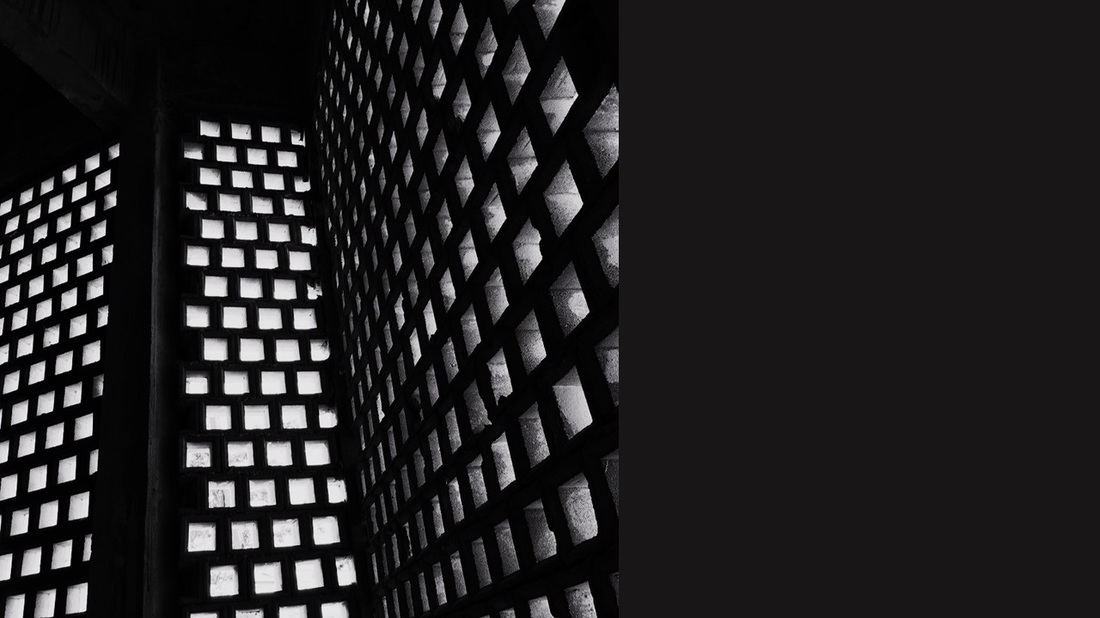

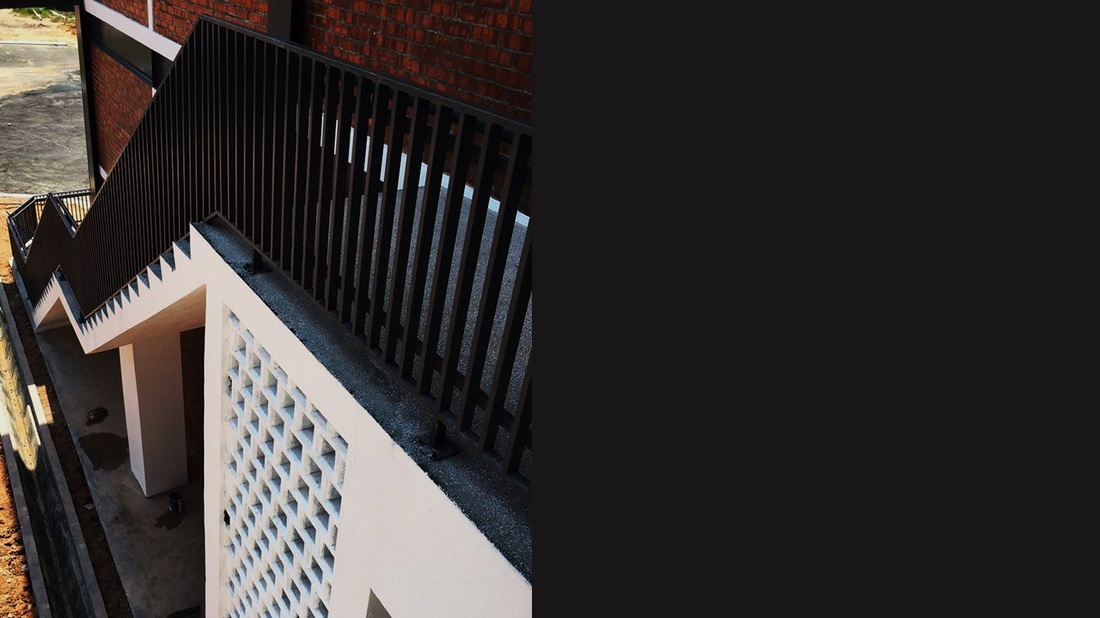

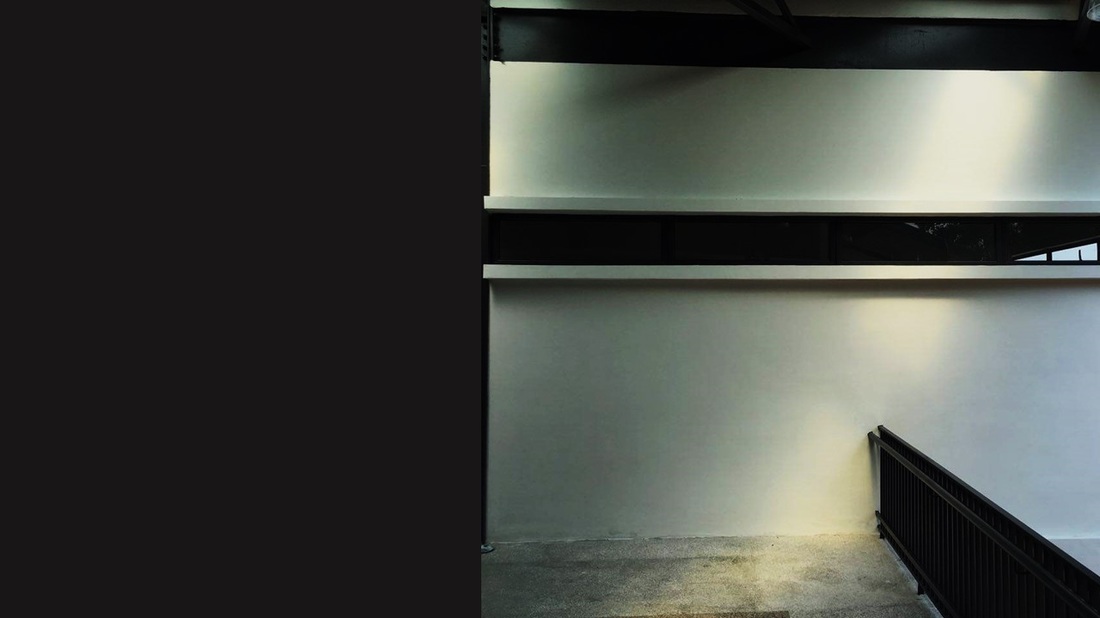

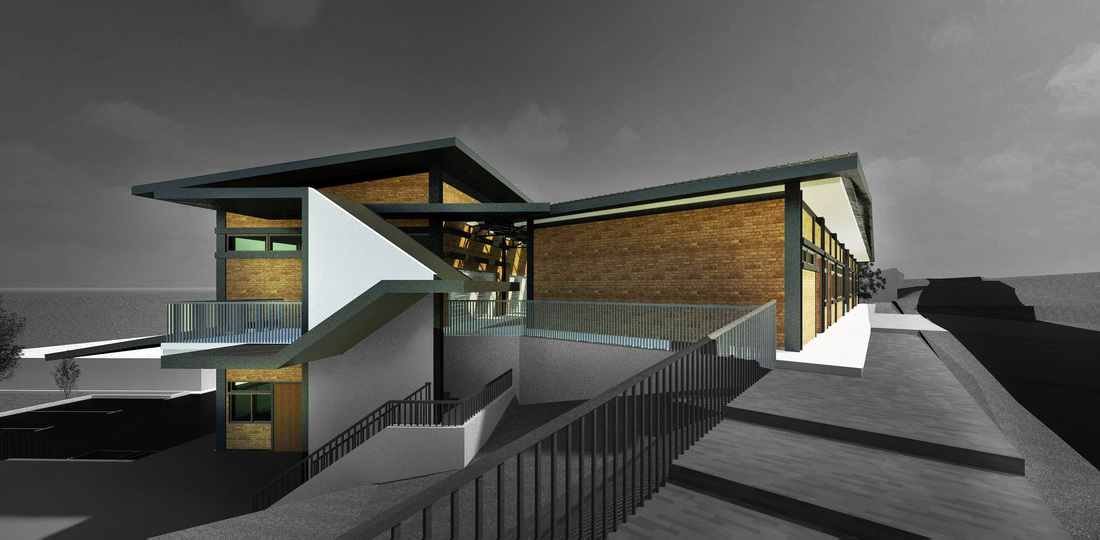

STEPS LINES PERFORATED WHITE WASH

Steps can be a single independent structure almost floating and this can be quite difficult to blend in. Using another medium the vent block, the Architect wish to melt the Common Brick wall with the Torso of Perforated vent block, creating a veil that blur between the line of public spaces with the private utility underneath of untreated slope. The series of balustrade form patterns within the repetitive edge of the veil of perforated vent block. The color contrast of the white wash foreground against the brown common clay background revealing again the natural beauty of materials in their raw form.

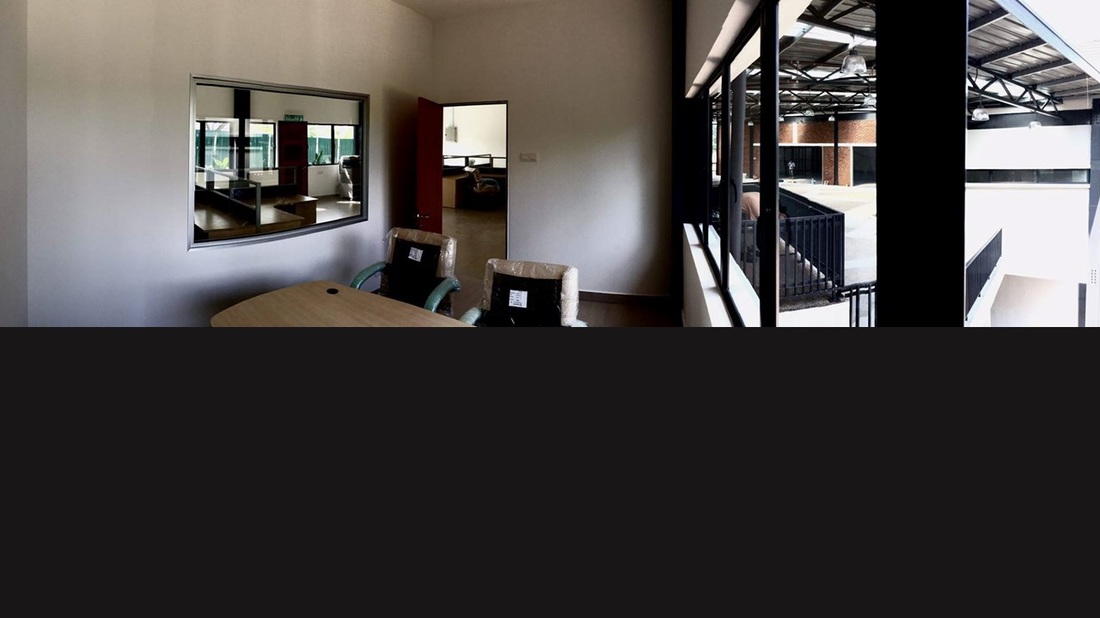

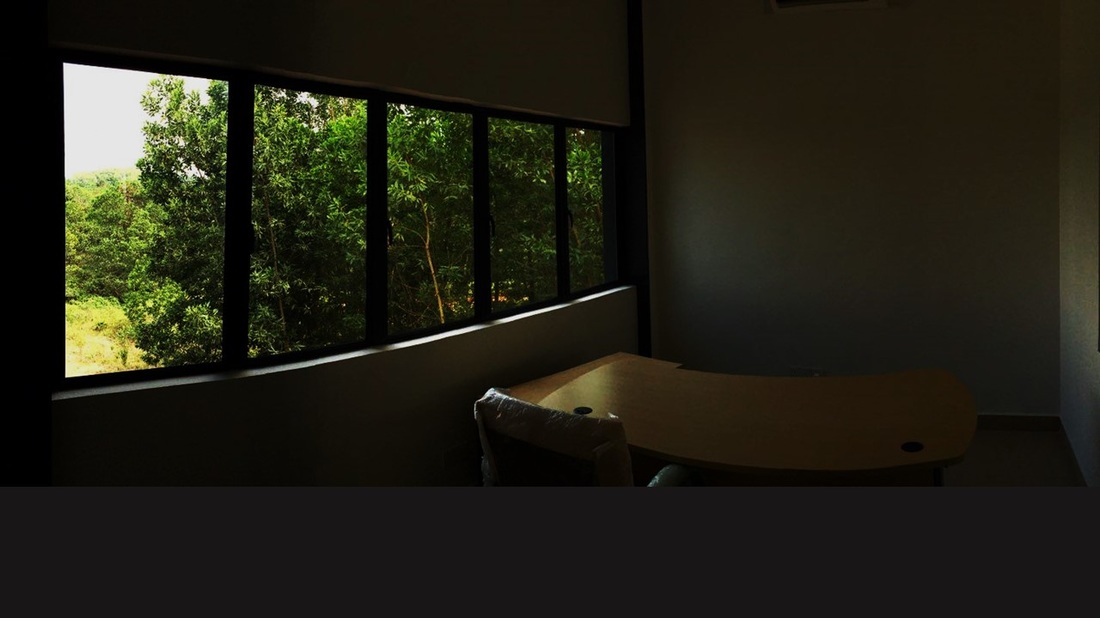

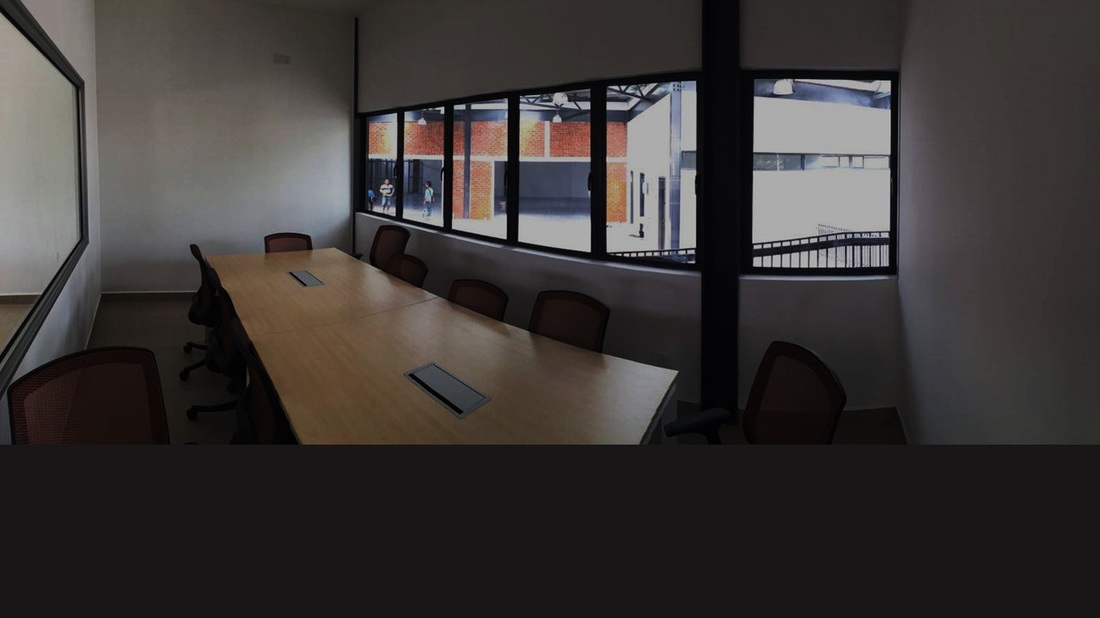

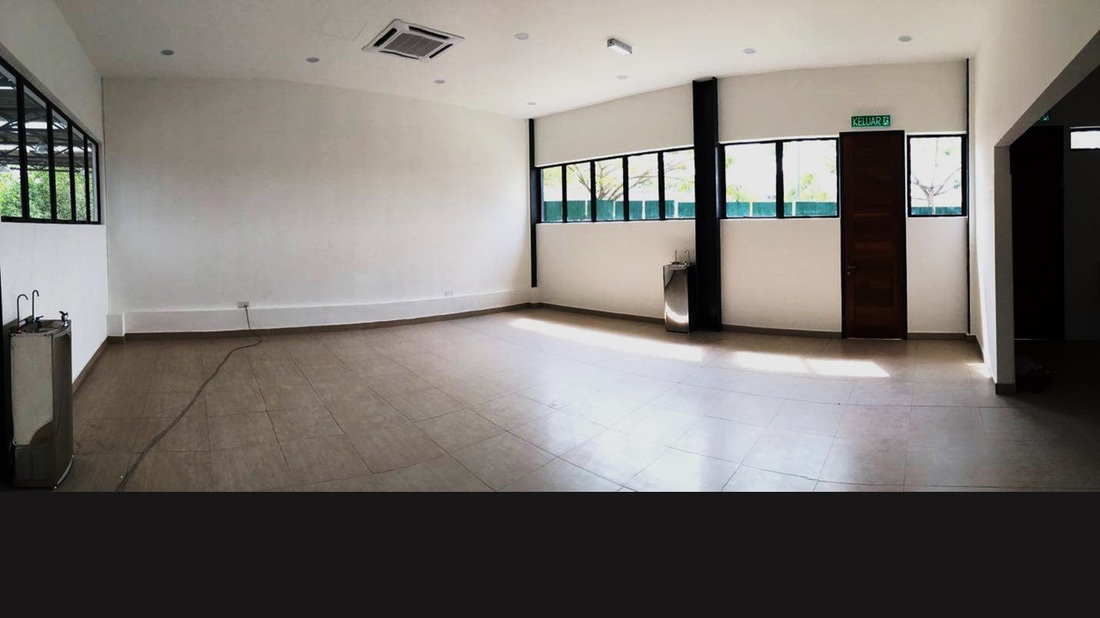

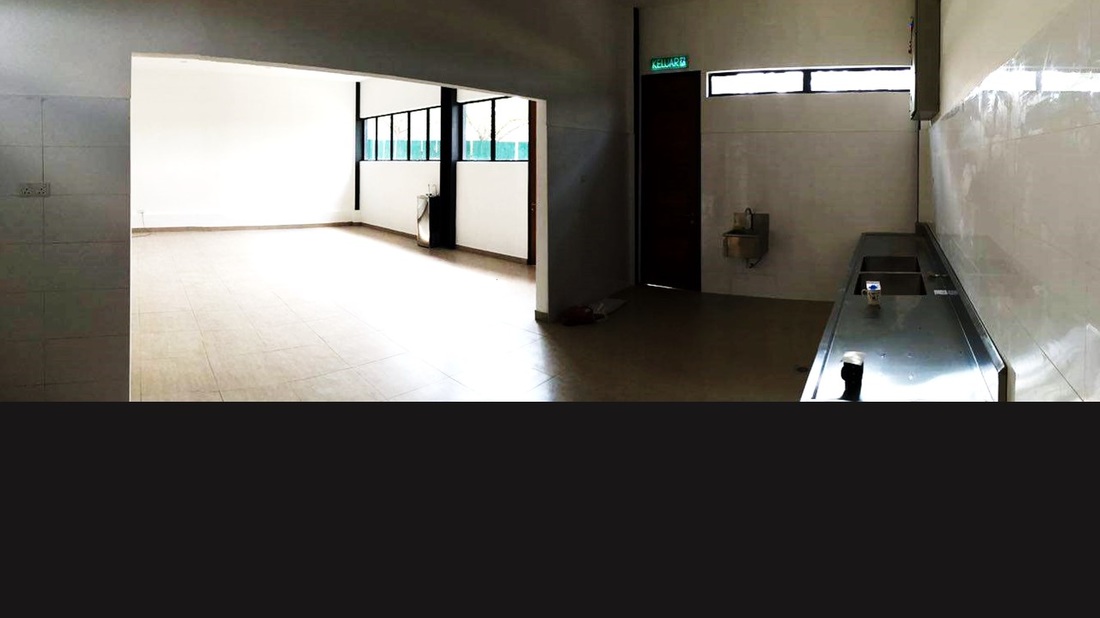

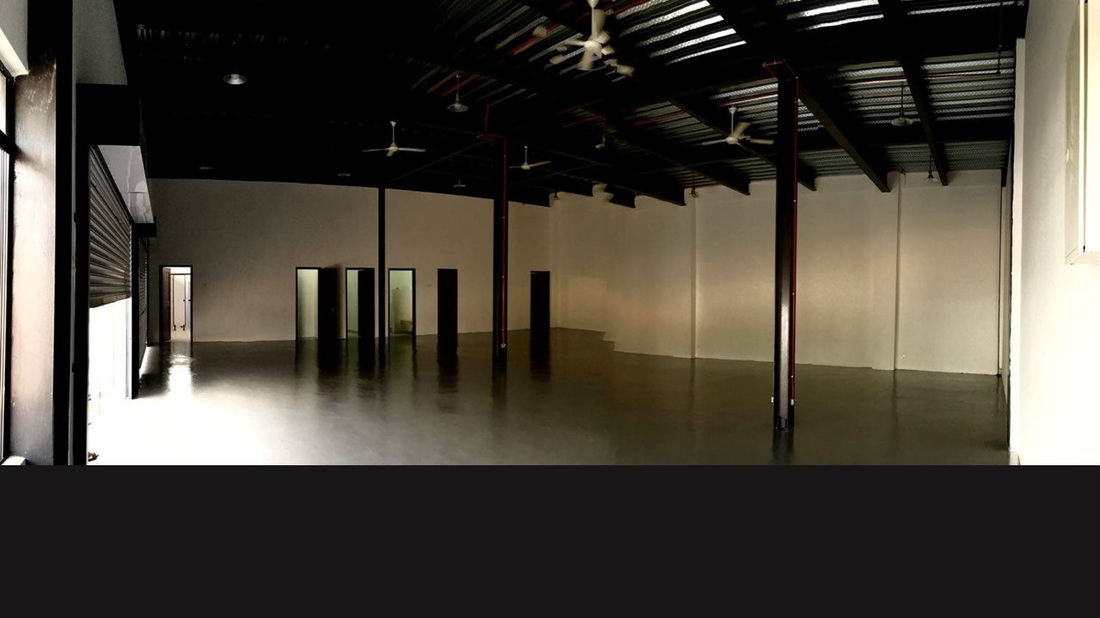

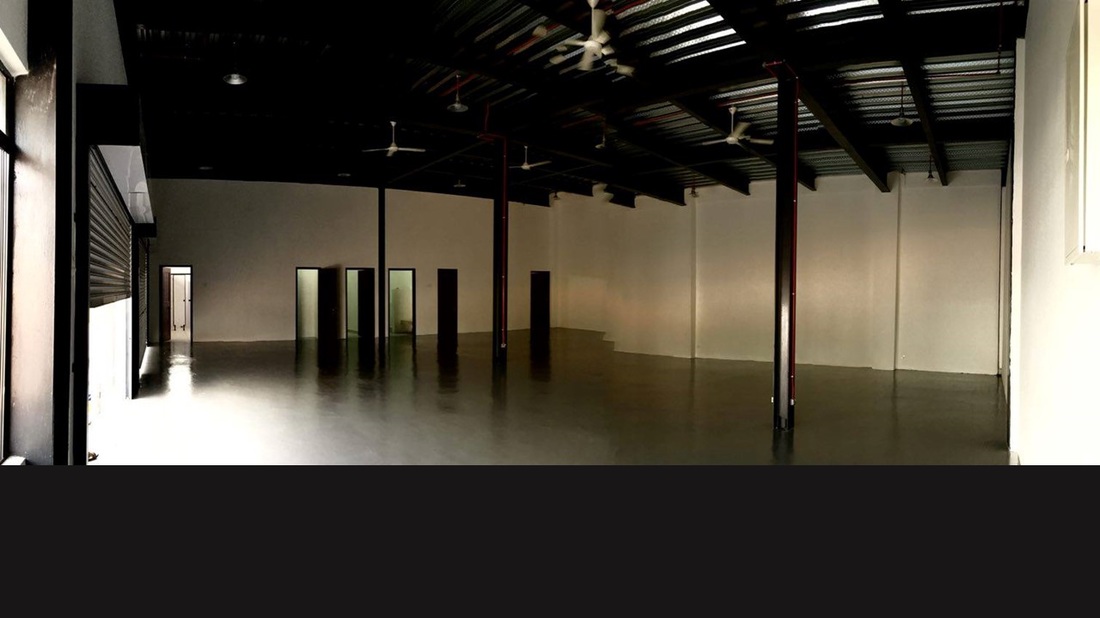

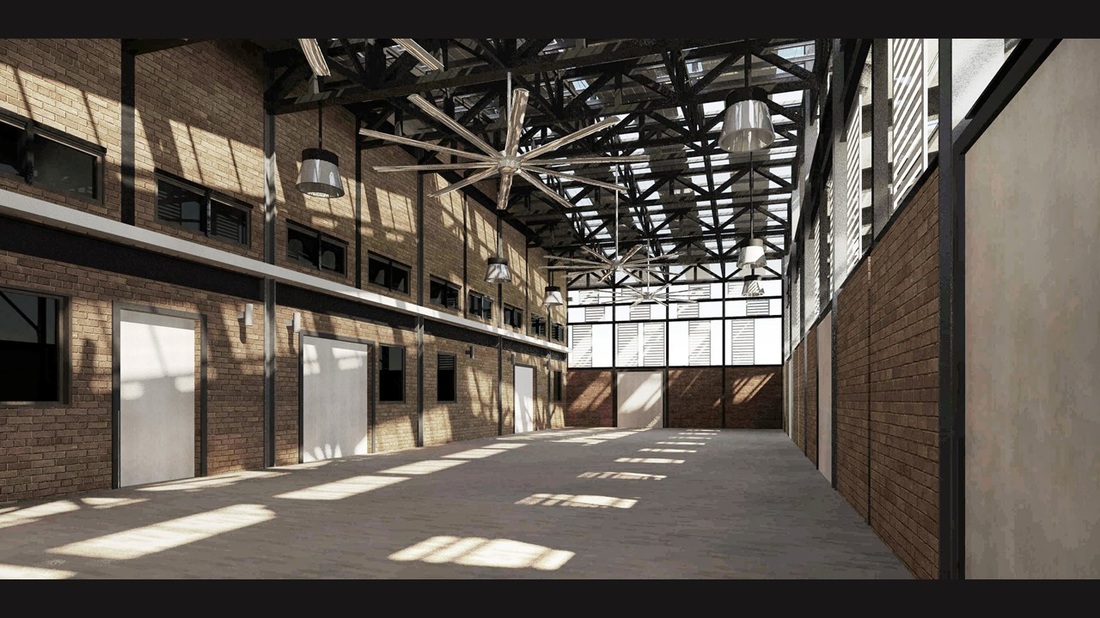

WORK COOK EAT STORAGE INTERIORS

Interiors of the office spaces, manager room and meeting rooms are all surrounded with views either toward the natural landscapes or the internal Plaza. There is always a connection between internal and external spaces either visually or physically. The canteen with its kitchenette are complementary of each other with high walls to allow fixture. The workshop is an unobstructed open spaces covered by the underside of the Bond Deck with proper power float flooring.

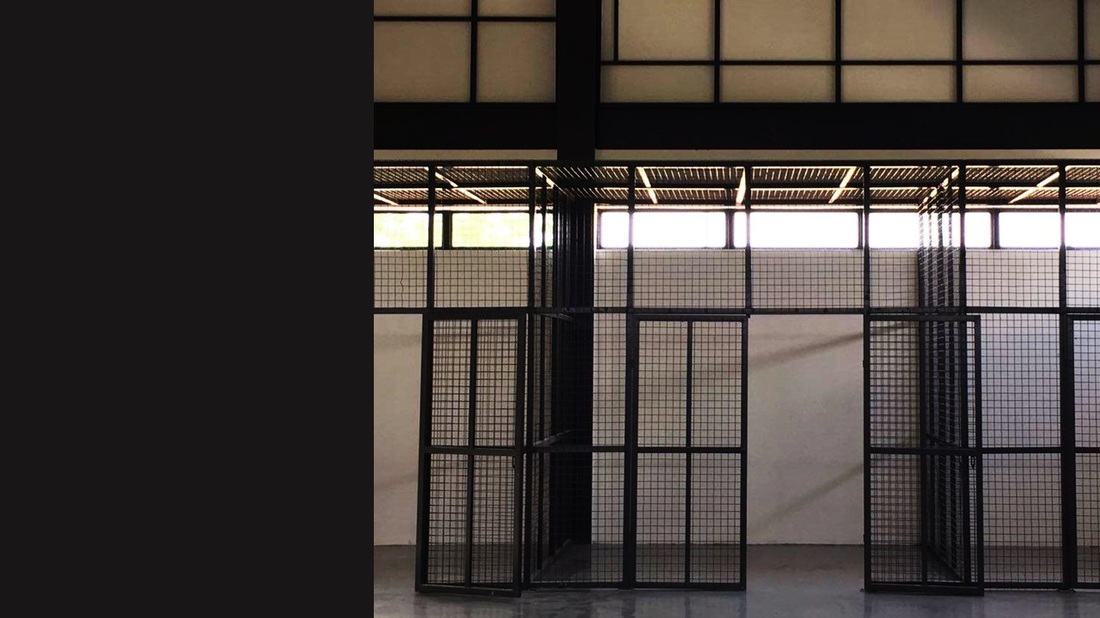

COLD STEEL CAGE PRISONS WORKSHOP

The strangest thing of this scheme is the storage area with Caging, apparently looking liked a prison within the school's compound. These caging are to safe guard some storage that does not belong to the school. Couple with the epoxy flooring, it gives a reflection to the otherwise dull apparent of the utility spaces with much "happening".

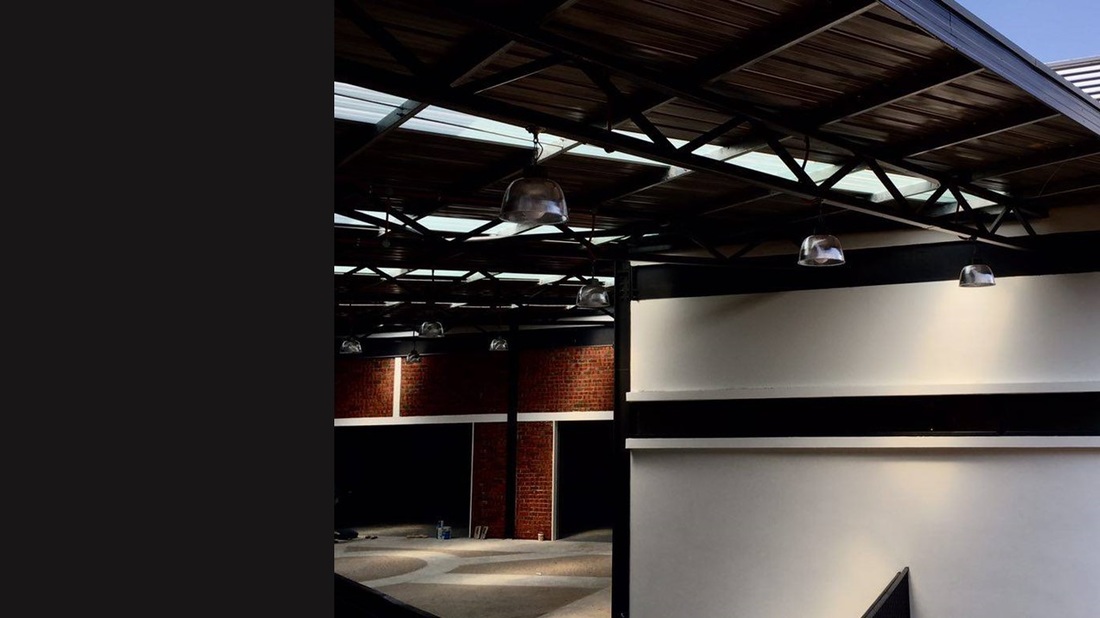

PLAZA STONE WASHED OPENESS AND LIGHT

The covered plaza is one of the intermediary spaces that glue the other utility spaces together. Peppered with stone wash, again trying to bring out the natural beauty of building materials without the need to concealing them. The striped metal roofing interlaced with transparent roofing sheet allows beam of sunlight penetrating to the internal spaces thus lighting up part of the walls, highlighting the natural materials against the sunlight. Such effect could be subliminal to the senses of the user. The entire framework with lattice girder and the sort shall create an atmosphere of temporal, unfinished and incomplete befitting the nature of the Estate House, that in other words mean - Maintenance Office.

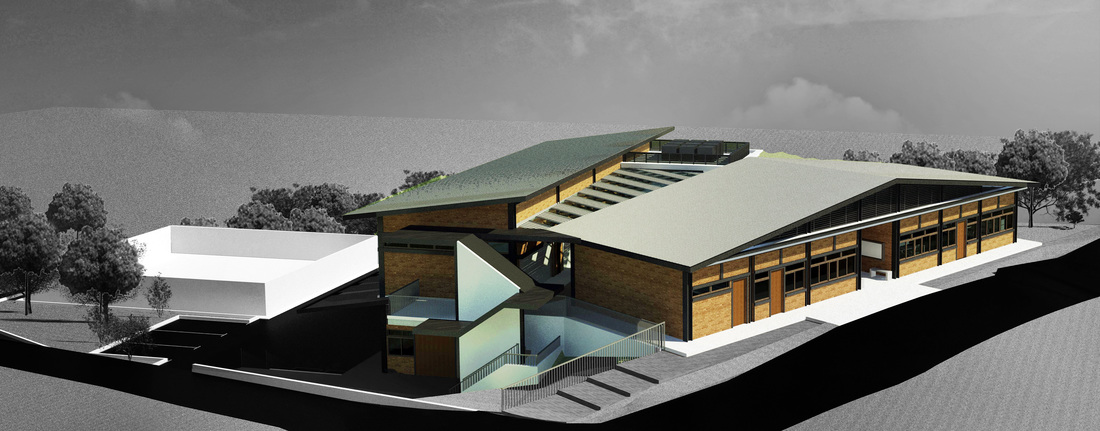

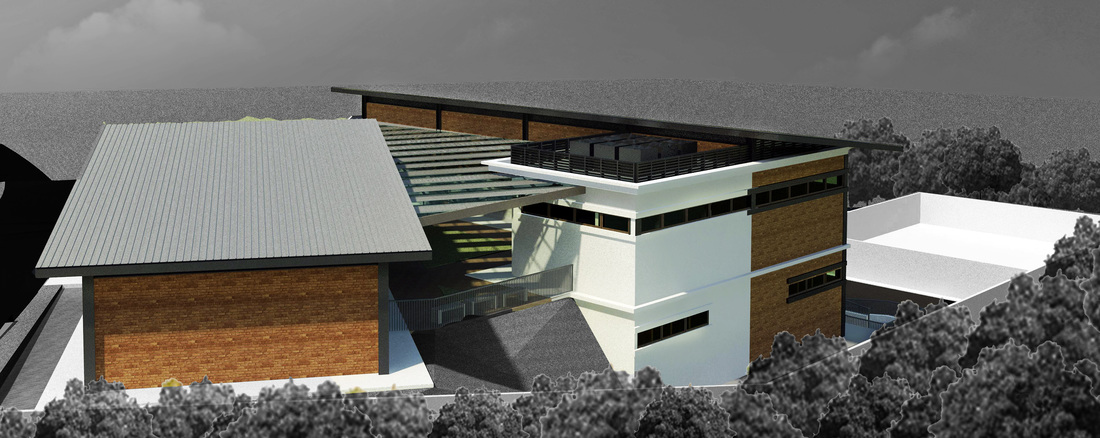

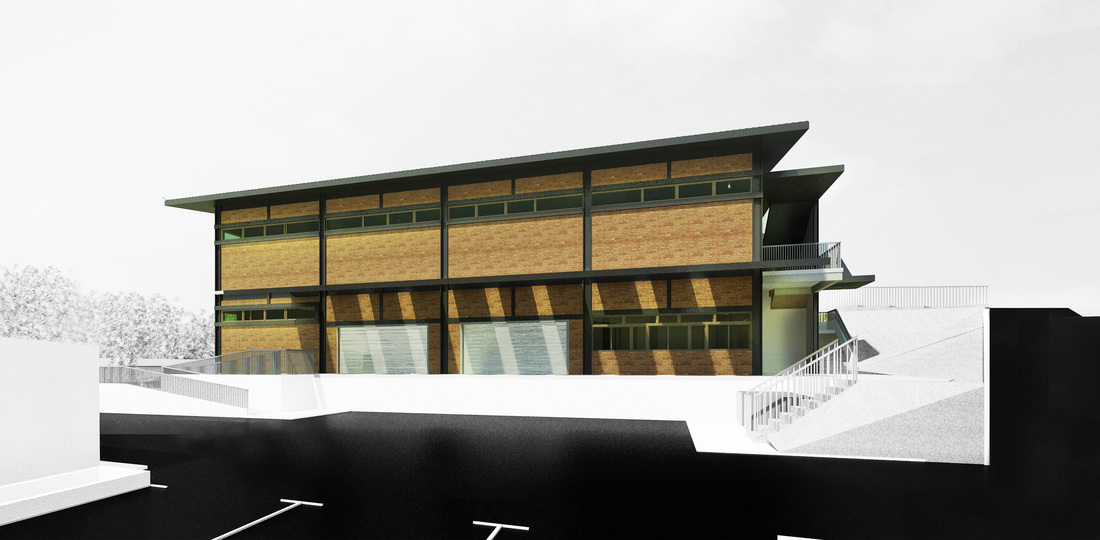

THE SITE

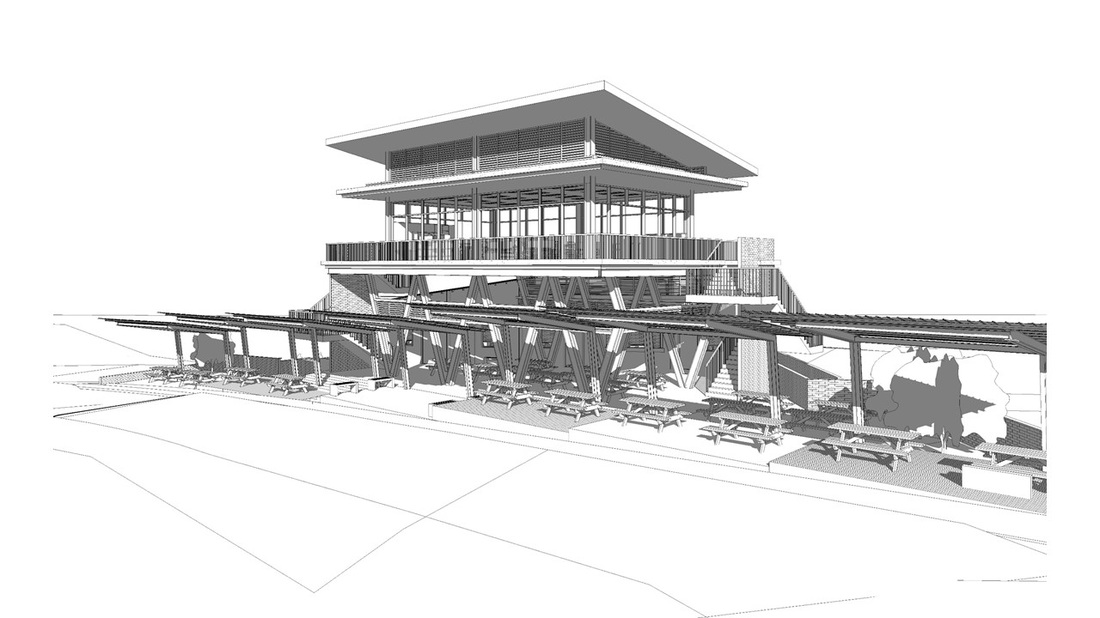

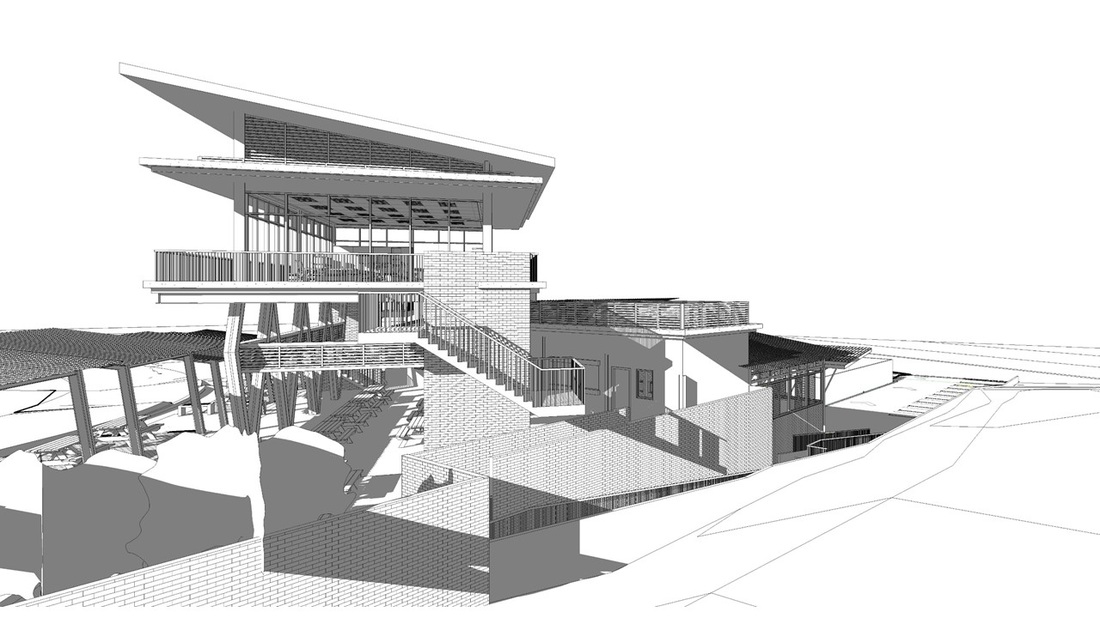

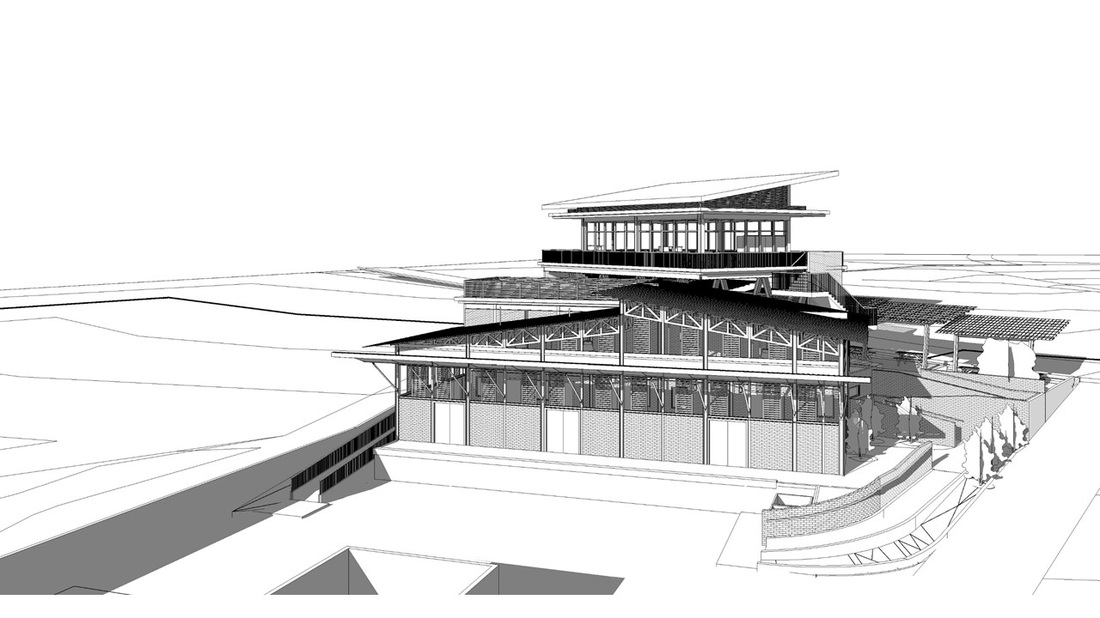

The site is located at the peripheral of the campus, on a sloping land overlooking the green vista of natural foliage and a stream. Perhaps we could proposed a canteen at road level, an elevated "tree house" office so that it can captured the entire vista, a workshop cum store house at the lowest level? Together we nicknamed it as the Estate House. This is actually the department of Estate and Property for the school.

THE SKETCH

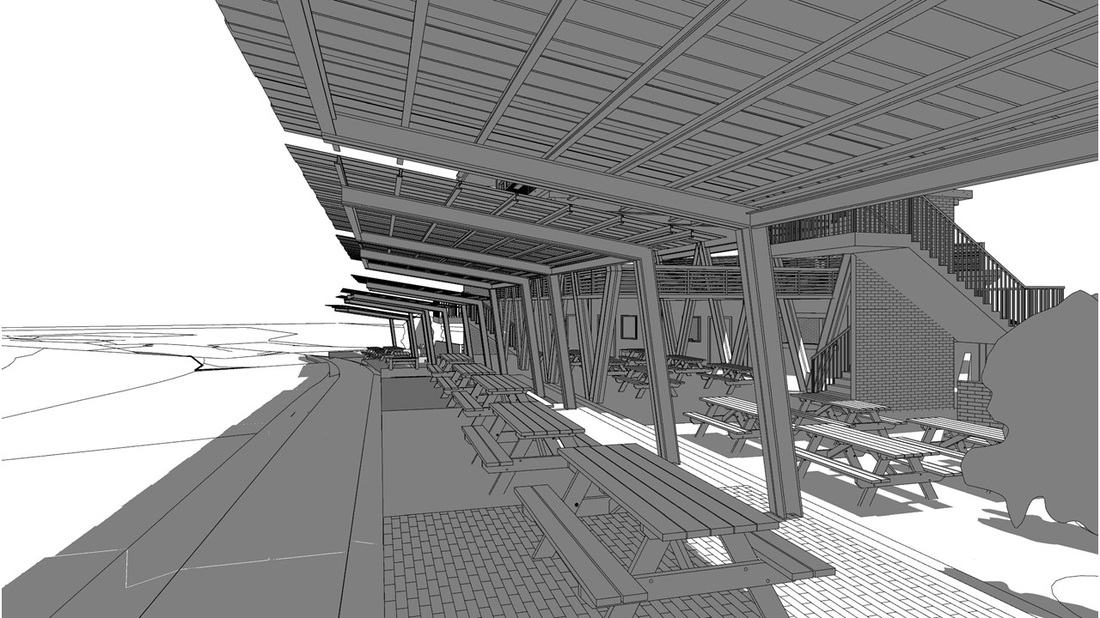

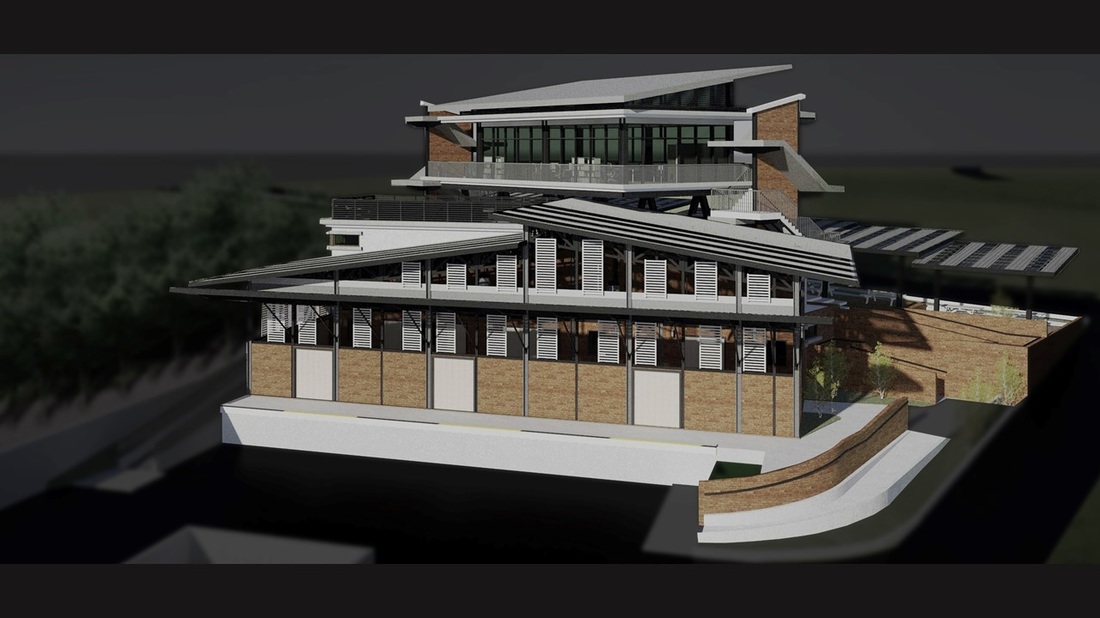

THE PROPOSAL

THE ALTERNATIVE

Generally budget cuts resulting in a more utilitarian out looked building. Trying to keep the initial idea of truth to materials, raw and minimalist approach. Space planning is rather straight forward - the classroom and office block fronting the road, the courtyard of canteen, huge store rooms accessible from the courtyard and below it, is the workshop with the docking and amenities.

THE CONSTRUCTION PROGRESS

FINISHES - 03.16

Near completion... Glimpses of things to come for the estate house... Almost complete with instant tree and we managed to save a number of matured trees... Internally it is a contrast - Heaven - internal courtyard for the estate house... Hell - didn't realise there are private prisons to lock up naughty pupils for the school in the estate house? Probably for the K-9 units? We could not make any justification if it is not captured in BnW to show the contrast of the natural materials. Subtleness - nothing more pleasurable watching the natural patterns offered by materials at their natural state...

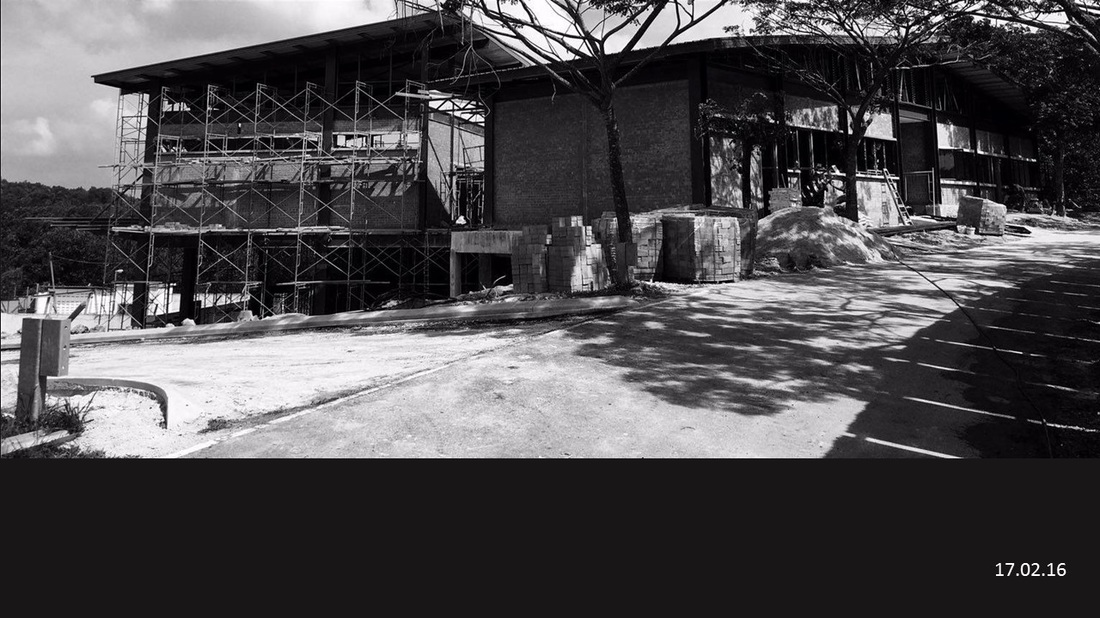

THE WALLS AND ROOF - 02.16

The superstructure for both the RC and Steel frame are up and ready to be installed with walls, roofs, cabling and to some extend infrastructure works including drainage, roads and landscape. The interior works for sanitary and plumbing were executed simultaneously with the prefabrication of the interior for the office spaces to be first delivered to the client ahead of schedule.

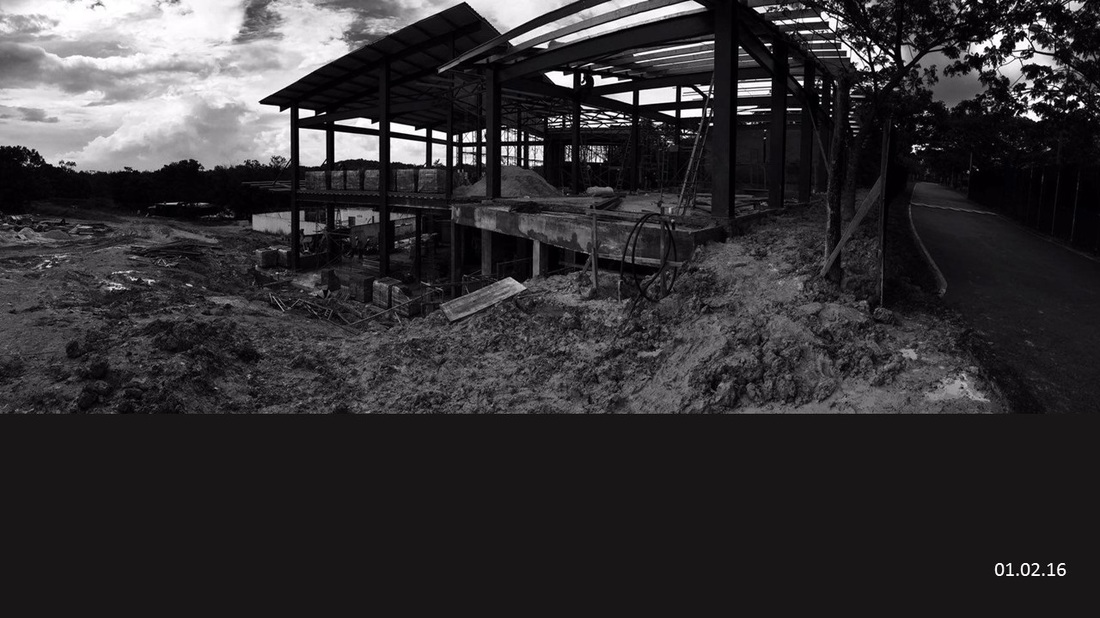

THE SUPERSTRUCTURE - 02.16

The contractor has sleep-ness night worrying that the concrete pour for the upper deck would result in the collapse of the form work for the slab due to its own weight while the scaffolding are only supported on soft soil conditions with bad weather. Using pump flow, the slab was able to be poured successfully and the good weather conditions help tremendously.

THE STEEL FRAME AND THE BONDDECK - 01.16

The employment of Steel Framing with Bond Deck has significantly save time. Yet due to the soft soil conditions the pouring of the Concrete Mix for the upper deck has been delayed. The lower deck Concrete Mix pouring has been completed on schedule. There are also challenges in terms of constructing the bracing of the scaffolding resting upon the slope.

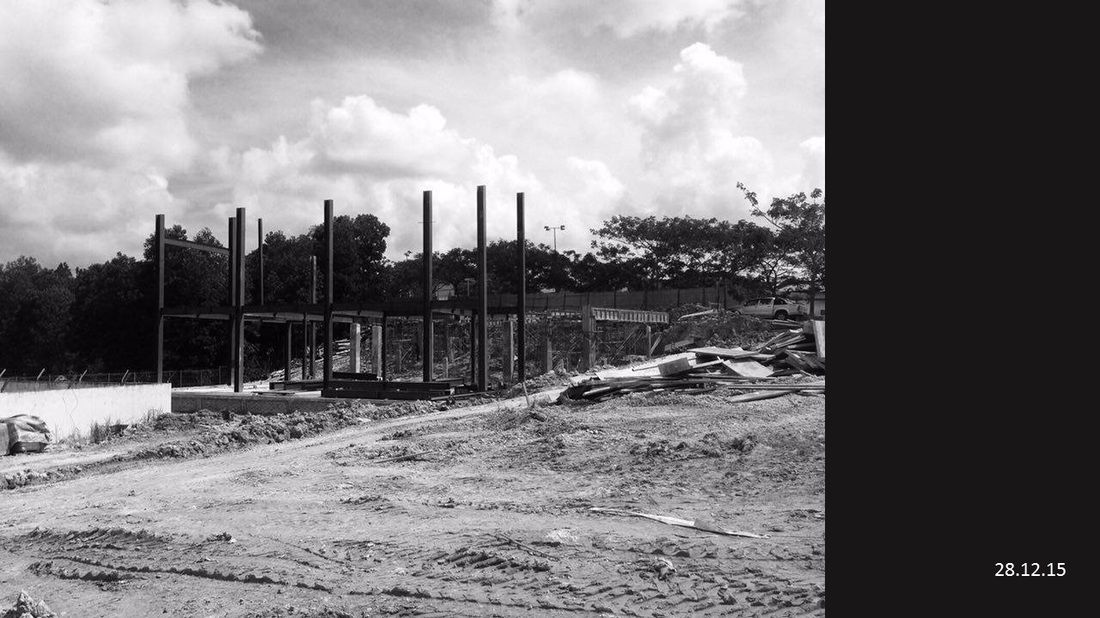

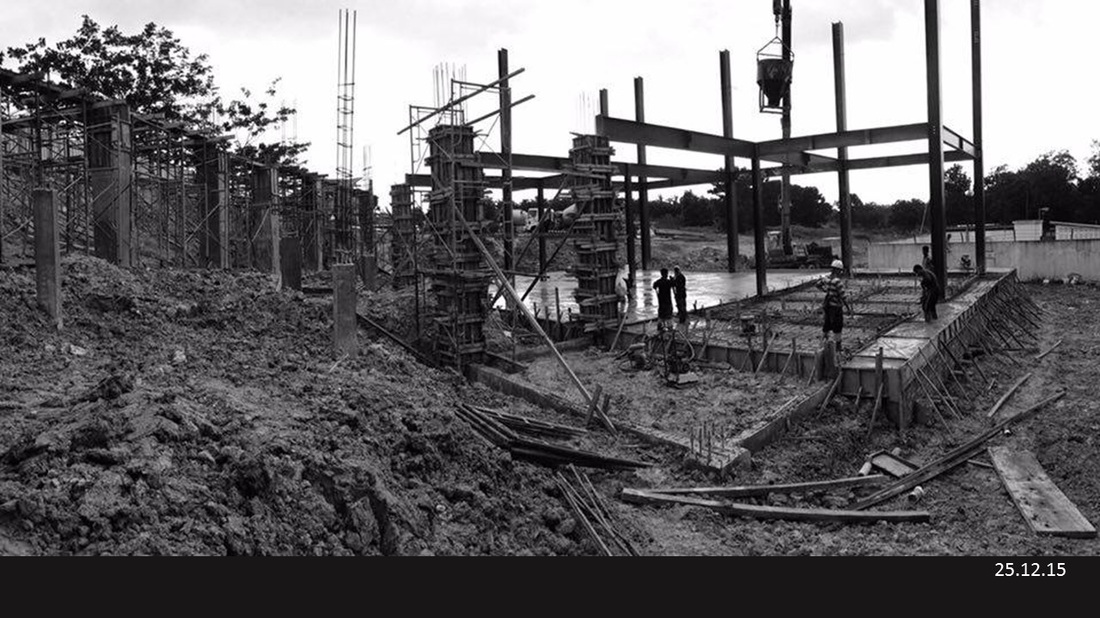

THE FORMWORK - 12.15

Upon completion of the substructure, the steel frames can be seen taking place at an advanced speed compared to the conventional RC structure. Formworks are required to cast up the RC slab in contrast to the Bond Deck for the steel frame. Again owing to the soft soil conditions, construction work was carried out slowly. again the factor of rain has reduce the speed originally intended for...

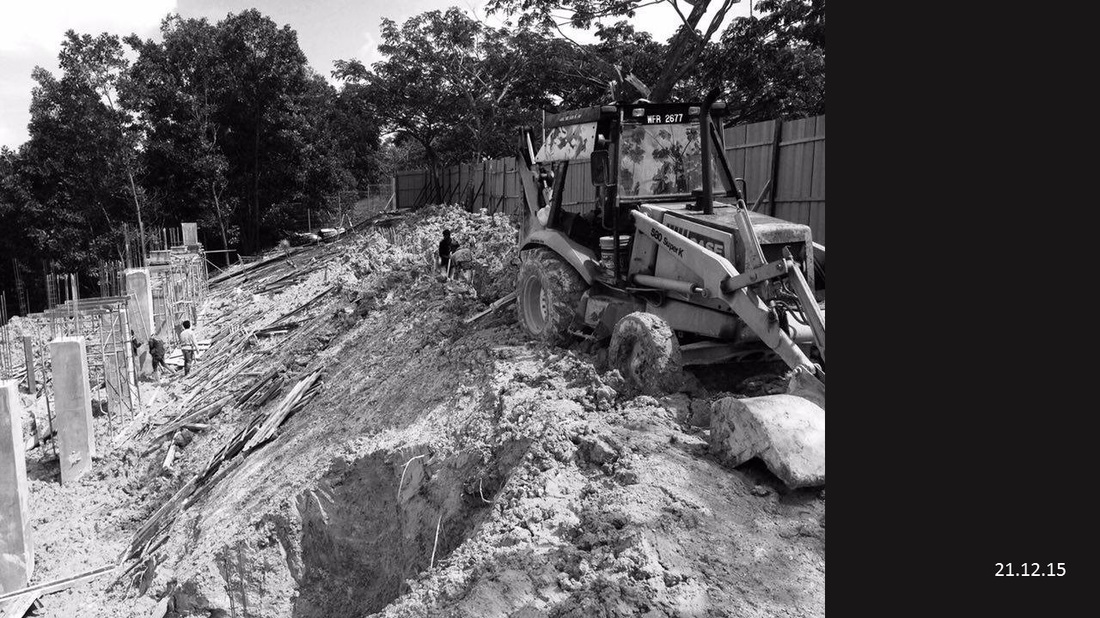

THE SUBSTRUCTURE - 12.15

Earthwork is a nightmare especially during the raining seasons and dealing with the slope. Apparently cost saving to reduce or to omit retaining wall, resulting in trimming of the slope to allow for the excavation of the footing. apparently the designed structural for the footing may have been oversized. This make the exercise even more challenging.